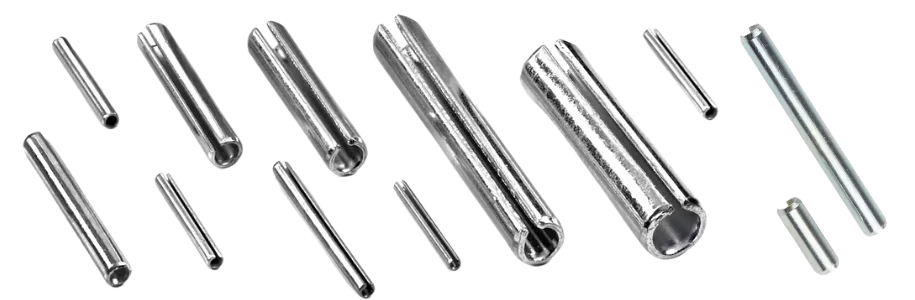

SPRING PIN

1. Precision Engineered Spring Pins for Reliable and Durable Solutions

DYN Fasteners brings you high-quality Spring Pins (also called tension pins or rolled pins), designed for a variety of mechanical applications where strength, durability, and reliability are essential. Manufactured to meet global standards, our Spring Pins offer excellent performance in dynamic and static loads, providing secure fastening solutions.

Spring Pins are hollow, cylindrical fasteners with a longitudinal slot. This slot allows the pin to compress and expand when inserted into a hole, ensuring a tight and secure fit. At DYN Fasteners, we use advanced manufacturing processes and high-quality materials to deliver Spring Pins that cater to industries requiring precision and performance.

- Spring Pins Features: High resistance to shear and vibration forces, Self-locking mechanism due to elastic properties, Corrosion resistance with superior finishes, Easy installation without requiring special tools, Available in multiple materials, grades, and finishes, Engineered to meet international standards.

- Typical Applications: Automotive Industry, Aerospace Industry, Industrial Machinery, Construction Equipment, Electronics Industry, Agriculture Equipment, Railways, Marine Industry.

- Finish Options: Plain (Self-finish), Zinc Plating (Yellow, Blue, and White Passivation), Black Oxide Coating, Phosphate Coating (Black or Grey), Galvanized Finish, Nickel Plating, Chrome Plating.

- Thread Types: Fully Threaded Spring pin (Tap Bolts), Partially Threaded Spring pin.

| Diameter (mm) | Length (mm) |

| 1.5 | 6, 8, 10, 12 |

| 3 | 12, 16, 20, 25 |

| 5 | 20, 25, 30, 40 |

| 8 | 40, 50, 60, 80 |

| 10 | 50, 60, 80, 100 |

TYPES OF MATERIALS USED IN SPRING PINS

- Carbon Steel: High strength and cost-effective solution.

- Stainless Steel: Resistant to corrosion; ideal for harsh environments.

- Alloy Steel: Enhanced mechanical strength and durability.

- Copper-Based Alloys: Ideal for electrical and thermal conductivity.

Chemical Composition:

| Material | C (%) | Mn (%) | Si (%) | S (%) | P (%) | Cr (%) | Ni (%) | Other |

| Carbon Steel (C1008) | 0.10 max | 0.30-0.50 | 0.10 max | 0.04 max | 0.04 max | – | – | – |

| Stainless Steel (SS304) | 0.08 max | 2.00 max | 1.00 max | 0.030 max | 0.045 max | 18.0-20.0 | 8.0-10.5 | – |

| Alloy Steel (4140) | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 max | 0.04 max | 0.80-1.1 | – | Mo (0.15-0.25) |

Mechanical Properties:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HRC) |

| Carbon Steel (C1008) | 350-500 | 200-300 | 35-45 |

| Stainless Steel (SS304) | 515-620 | 205-290 | 20-30 |

| Alloy Steel (4140) | 750-1000 | 650-850 | 40-50 |

- Standards:

ISO 8752.

DIN 1481.

ASTM F2438.

BS 7051.

- Certifications: CE Certification, RoHS Compliant, REACH Compliance.