NAILS

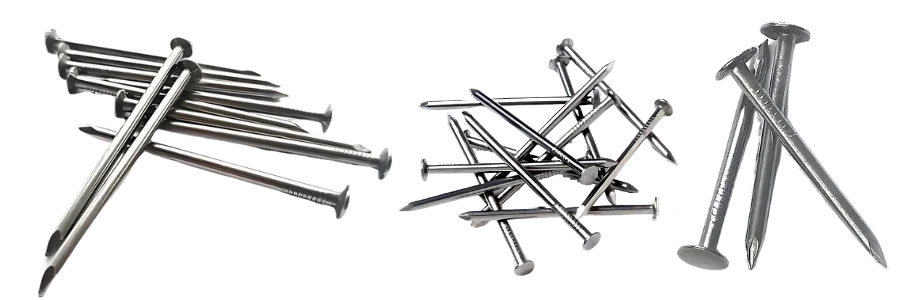

1. Common Nails – Versatile Fastening Solutions for Construction and Woodworking

Common nails are one of the most widely used types of nails in construction and woodworking. Designed for strength and durability, these nails provide reliable connections between various materials, making them essential for a variety of applications. At DYN Fasteners, we offer high-quality common nails that meet industry standards, ensuring performance and reliability for your projects.

Design: Common nails typically feature a long, cylindrical shaft with a sharp, pointed end for easy penetration and a flat head that provides a large bearing surface. This design allows for effective fastening in a variety of materials, including wood and some light masonry.

Function: Common nails are primarily used to join pieces of wood together and are ideal for framing, general construction, and various woodworking applications.

- Common Nails Features: High Strength, Versatile Applications, Easy Installation, Durable Construction, High Holding Power, Cost-Effective Solution, Ease of Use.

- Typical Applications: Construction, Woodworking, Manufacturing,

- Finish Options: Bright Finish, Galvanized Finish, Electro-Galvanized, Hot-Dipped Galvanized, Vinyl Coating, Cement-Coated, Polymer Coating, Stainless Steel, Phosphate Coated, Black Oxide, Copper-Plated, Zinc-Plated, Blued Finish, Epoxy Coated.

Common Nails Size Guide and Specifications:

| Length (inches) | Length (mm) | Diameter (inches) | Diameter (mm) | Head Type |

| 2 | 50 | 0.099 | 2.5 | Flat |

| 3 | 75 | 0.113 | 2.9 | Flat |

| 4 | 100 | 0.131 | 3.3 | Flat |

| 5 | 125 | 0.148 | 3.8 | Flat |

| 6 | 150 | 0.162 | 4.1 | Flat |

Custom sizes and specifications are available upon request.

2. Finish Nails – Precision Fastening for A Polished Look

Finish nails are specialized fasteners designed for precise applications where a clean and unobtrusive finish is essential. These nails are commonly used in woodworking, cabinetry, and trim work, allowing for seamless integration into finished surfaces. At DYN Fasteners, we provide high-quality finish nails that deliver exceptional performance and aesthetic appeal for all your projects.

Design: Finish nails feature a slender, elongated shaft with a small, flat or slightly rounded head. Their design minimizes the visibility of the nail after installation, making them ideal for projects where appearance is a priority.

Function: The primary purpose of finish nails is to secure trim, moldings, and other decorative elements in woodworking and construction projects while leaving a minimal mark on the finished surface.

- Finish Nails Features: Small Head, Variety of Lengths, Smooth Shank, Durable Construction, Aesthetic Finish, Versatile Use, Easy Installation, Strong Holding Power.

- Typical Applications: Trim Work, Cabinetry, Woodworking.

- Finish Options: Bright Finish, Galvanized Finish, Electro-Galvanized, Hot-Dipped Galvanized, Vinyl Coating, Cement-Coated, Polymer Coating, Stainless Steel, Phosphate Coated, Black Oxide, Copper-Plated, Zinc-Plated, Blued Finish, Epoxy Coated.

| Length (inches) | Length (mm) | Diameter (inches) | Diameter (mm) | Head Type |

| 1 | 25 | 0.08 | 2 | Flat |

| 1.25 | 32 | 0.08 | 2 | Flat |

| 1.5 | 38 | 0.09 | 2.3 | Flat |

| 2 | 50 | 0.09 | 2.3 | Flat |

| 2.5 | 63 | 0.09 | 2.3 | Flat |

3. Brad Nails – Precision Fastening for Delicate Woodworking

Brad nails are thin-gauge nails designed for light-duty fastening where a delicate touch is needed. These nails are typically used in fine woodworking projects, trim installations, and smaller-scale carpentry tasks. At DYN Fasteners, we offer high-quality brad nails that are ideal for applications requiring precision, minimal surface disruption, and a clean finish.

Design: Brad nails feature a thin, slender shaft with a small head that nearly disappears into the material when driven. This makes them perfect for attaching lightweight trim and delicate wood pieces where larger nails would cause splitting or an unsightly finish.

- Brad nails Features: Small Diameter, Smooth Shank, Subtle Head, Variety of Lengths, Minimal Surface Disruption, Prevents Wood Splitting, Precision Fastening, Easy to Conceal, Efficient Installation.

- Typical Applications: Trim and Molding, Cabinetry and Furniture, Picture Framing.

- Finish Options: Bright Finish, Galvanized Finish, Electro-Galvanized, Hot-Dipped Galvanized, Vinyl Coating, Cement-Coated, Polymer Coating, Stainless Steel, Phosphate Coated, Black Oxide, Copper-Plated, Zinc-Plated, Blued Finish, Epoxy Coated.

| Length (inches) | Length (mm) | Diameter (gauge) | Diameter (mm) | Head Type |

| 1 | 25 | 18 | 1.02 | Small |

| 1.25 | 32 | 18 | 1.02 | Small |

| 1.5 | 38 | 18 | 1.02 | Small |

| 2 | 50 | 18 | 1.02 | Small |

| 2.5 | 63 | 18 | 1.02 | Small |

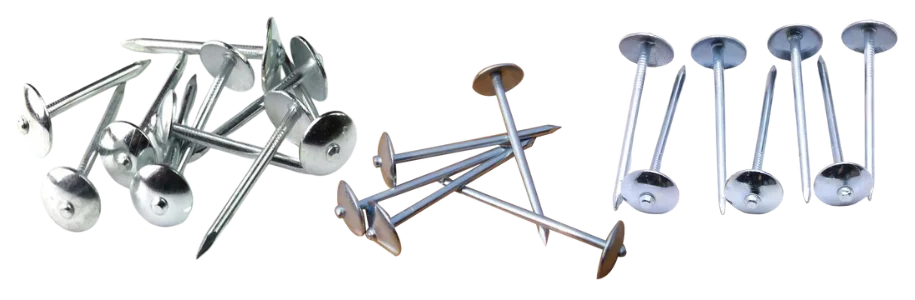

4. Roofing Nails – Superior Fastening for Durable Roofing Systems

Roofing nails are essential fasteners specifically designed to secure roofing materials like shingles, tiles, and sheet metal to various substrates. At DYN Fasteners, we provide high-quality roofing nails that offer exceptional durability, corrosion resistance, and holding power for residential, commercial, and industrial roofing projects.

Design: Roofing nails have a large, flat head to prevent tearing of roofing materials, combined with a short shank for strong holding power. The shaft of the nail can be smooth or twisted (ring-shank or spiral-shank) to improve grip and resistance against high winds or external forces.

Function: These nails are used to secure shingles, roofing felt, waterproof membranes, and roofing insulation to wooden or metal roof decks. Their design minimizes the chance of the roofing material pulling away or shifting, ensuring long-term durability of the roof structure.

- Roofing nails Features: Large, Flat Head, Corrosion Resistance, Shank Options, Variety of Lengths and Gauges, Weather Resistance, Superior Holding Power, Durability, Versatility, Easy to Install.

- Typical Applications: Asphalt and Composite Shingles, Roofing Felt and Waterproof Membranes, Metal Roofing, Roofing Insulation and Flashing.

- Finish Options: Bright Finish, Electro-Galvanized, Hot-Dipped Galvanized, copper-plated steel, plastic or polymer coating, vinyl coating, Painted Finish.

| Length (inches) | Shank Diameter (gauge) | Head Diameter (inches) | Shank Type |

| 3/4 | 11 | 3/8 | Smooth |

| 1 | 11 | 3/8 | Ring-shank |

| 1 1/4 | 11 | 3/8 | Spiral-shank |

| 1 1/2 | 11 | 3/8 | Smooth/Ring-shank |

| 2 | 10 | 3/8 | Smooth/Ring-shank |

5. Masonry Nails – Tough and Durable for Hard Surfaces

Masonry nails are specifically designed for fastening materials to hard surfaces like concrete, brick, and stone. Their unique design and construction allow them to penetrate dense and rigid materials without bending or breaking, making them essential for construction, repair, and renovation projects that involve masonry work.

Design: Masonry nails are thick, sturdy, and feature a hardened, tapered body that enables them to withstand the pressure of being driven into tough surfaces like brick and concrete. Their shaft can come in a variety of styles, such as square, fluted, or round, to offer maximum penetration and gripping power in masonry materials.

Function: These nails are primarily used to fasten wood, metal, or other materials to masonry surfaces, ensuring secure and long-lasting attachments. Masonry nails can also be used in situations where standard nails would be ineffective due to bending or breaking when driven into hard materials.

- Masonry nails Features: Hardened Steel Construction, Tapered Design, Variety of Shank Types, Round Shank, Fluted Shank, Square Shank, Corrosion Resistance, Sharp Point, Strong and Durable, Superior Holding Power, Corrosion Resistance, Wide Range of Applications, Easy Installation.

- Typical Applications: Attaching Wooden Studs to Masonry Walls, Securing Furring Strips to Concrete or Brick Surfaces, Fastening Metal Components to Brick or Stone, Mounting Fixtures on Masonry, Outdoor Projects.

- Finish Options: Bright Finish, Galvanized Finish, Hardened Steel with Black Oxide Finish, Stainless Steel Finish, Zinc-Plated Finish, Blue Hardened Steel Finish, Phosphate-Coated Finish, Vinyl-Coated Finish.

| Length (inches) | Shank Diameter (gauge) | Shank Type |

| 1 1/2 | 9 | Square |

| 2 | 9 | Round |

| 2 1/2 | 8 | Fluted |

| 3 | 7 | Square |

| 3 1/2 | 6 | Round |

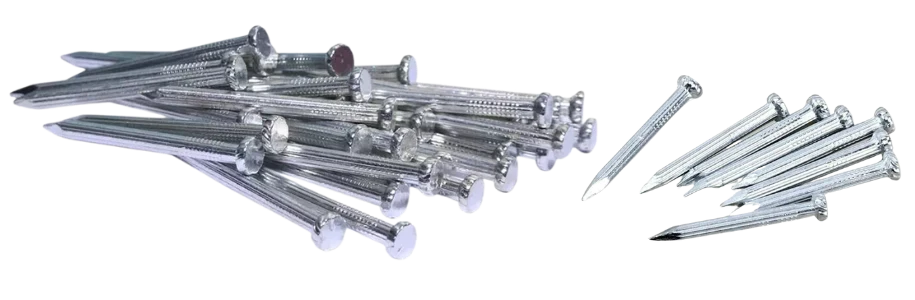

6. Concrete Nails – Strong Fastening for Tough Materials

Concrete nails are heavy-duty fasteners designed to drive into extremely hard materials such as concrete, masonry, and stone. Manufactured from hardened steel, they are engineered to deliver superior strength and durability in construction and renovation projects. Concrete nails are ideal for affixing wood, metal, or other materials to concrete surfaces where standard nails would bend or break.

Design: Concrete nails have a robust design featuring a thick, hardened steel body that ensures penetration into dense materials. Their shafts are either smooth or grooved, and their pointed tips allow them to pierce through hard surfaces with ease.

Function: These nails are used primarily for securing wood or metal materials to concrete, brick, or block surfaces. Their sturdy construction makes them ideal for construction and repair projects involving hard surfaces.

- Concrete nails Features: Hardened Steel, Smooth or Grooved Shanks, Sharp Pointed Tip, Corrosion-Resistant Coating, Superior Strength, Tight Hold, Corrosion Resistance, Versatility, Easy to Use.

- Typical Applications: Securing Wooden Frames to Concrete Surfaces, Attaching Furring Strips to Concrete, Fastening Metal or Wood Fixtures, Installing Exterior Cladding, Attaching Trim or Baseboards to Concrete Floors.

- Finish Options: Bright Finish, Galvanized Finish, Black Oxide Finish, Blue Hardened Steel Finish, Stainless Steel Finish, Zinc-Plated Finish, Phosphate-Coated Finish, Vinyl-Coated Finish, Epoxy-Coated Finish.

| Length (inches) | Shank Diameter (gauge) | Shank Type |

| 1 1/2 | 12 | Smooth |

| 2 | 11 | Fluted |

| 2 1/2 | 10 | Grooved |

| 3 | 9 | Smooth |

| 4 | 8 | Grooved |

Bolts Materials / Grades

| Material | Grades |

| Low Carbon Steel | SAE 1006, 1008, 1010 |

| Low/Medium Carbon Steel | SAE 1006, 1008, 1010, 1015 |

| Medium Carbon Steel | SAE 1045, 1050 |

| High Carbon Steel | SAE 1060, 1070, 1080 |

| Stainless Steel | A2 (304), A4 (316) |

| Aluminum Alloy | 5052, 6061 |

| Pure Copper/Copper Alloys | C110 (Copper), Brass |

| Low Carbon Steel | SAE 1006, 1008, 1010 |

| Medium Carbon Steel | SAE 1045, 1050 |

| Medium Carbon Steel | SAE 1045, 1050 |

| Medium/High Carbon Steel | SAE 1045, 1060, 1070 |

| High Carbon Steel | SAE 1060, 1070, 1080 |

- Standards:

ISO 9001.

ASTM f667. - Certifications: CE Certification, RoHS Compliant, REACH Compliance.