COIL SPRINGS

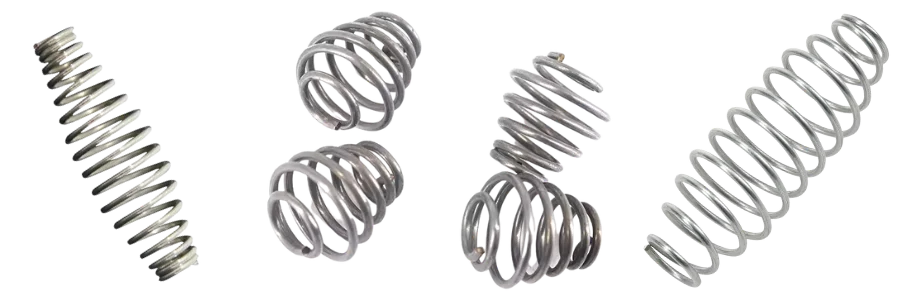

1. Dyn Fasteners Compression Springs

DYN Fasteners is a trusted exporter of Compression Springs, delivering high-performance, durable, and precision-engineered solutions for a wide range of applications. Compression Springs are a critical component in many mechanical systems, designed to store and release energy under compressive forces.

Our springs are crafted with advanced manufacturing techniques and stringent quality checks to ensure optimum functionality and longevity. Whether for industrial machinery, automotive systems, or electronics, DYN Fasteners Compression Springs are tailored to meet global standards, delivering consistent and reliable performance.

By choosing DYN Fasteners, you gain access to springs with superior load-bearing capacity, excellent dimensional accuracy, and finishes that enhance corrosion resistance, ensuring unmatched value for your operations.

- Compression Springs Features: High Durability, Customizability, Corrosion Resistance, Precision Engineering, Versatile Applications, Cost-Effective.

- Typical Applications: Automotive Industry, Aerospace Industry, Industrial Equipment, Electronics Industry, Railway Industry, Construction and Mining Equipment, Medical Devices, General Applications.

- Finish Options: Electroplating, Powder Coating, Phosphating, Passivation, Oil Coating, Black Oxide, Hot Dip Galvanizing, Teflon Coating.

| Type of Compression Spring | Free Length (mm) | Wire Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Compressed Length (mm) | Solid Height (mm) |

| 1. Automotive Suspension Coil Springs | ||||||

| Passenger Cars | 200 – 400 | 10 – 15 | 100 – 130 | 70 – 110 | 150 – 300 | 100 – 150 |

| Trucks and SUVs | 400 – 600 | 12 – 20 | 130 – 160 | 100 – 140 | 300 – 500 | 150 – 250 |

| 2. Industrial Equipment Coil Springs | ||||||

| Heavy Machinery (Excavators, Cranes) | 500 – 1000 | 18 – 30 | 150 – 250 | 120 – 200 | 300 – 800 | 200 – 400 |

| Vibration Dampening Systems | 100 – 250 | 05-10 | 50 – 100 | 40 – 80 | 75 – 150 | 50 – 100 |

| 3. Railway Coil Springs | ||||||

| Railway Springs | 500 – 900 | 20 – 35 | 160 – 250 | 120 – 210 | 400 – 700 | 200 – 350 |

| 4. General Purpose Compression Springs | ||||||

| Light-Duty Springs (Electronics) | Oct-50 | 0.5 – 1.5 | 05-10 | 4 – 8 | 5 -30 | 3 – 10 |

| Medium-Duty Springs | 50 – 150 | 2-5 | 20 – 50 | 15 – 45 | 30 – 100 | 20 – 60 |

| 5. Construction Equipment Coil Springs | ||||||

| Load-Bearing Springs | 600 – 1000 | 25 – 40 | 200 – 300 | 160 – 260 | 400 – 800 | 250 – 500 |

| Vibration Isolation Springs | 200 – 400 | 8 -20 | 80 – 150 | 60 – 120 | 150 – 300 | 100 – 200 |

| 6. Custom Coil Springs | ||||||

| Small Springs (General Use) | Oct-50 | 0.5 – 5 | 5 -50 | 4 – 40 | 5 – 100 | 3 – 30 |

| Medium Springs | 50 – 150 | 5 -20 | 50 – 150 | 40 – 120 | 50 – 200 | 30 – 60 |

| Large Springs | 150 – 500 | 20 – 40 | 150 – 300 | 120 – 260 | 100 – 400 | 60 – 150 |

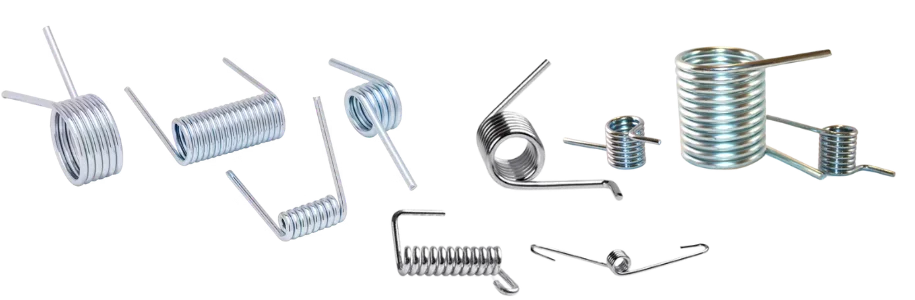

2. Precision Engineered Torsion Springs for Reliable Performance

Torsion springs are mechanical components that store and release rotational energy. They are designed to resist twisting forces, which make them crucial in a variety of applications where rotational motion or torque is required. At DYN Fasteners, our torsion springs are crafted with high-quality materials and precision engineering to ensure long-lasting durability, excellent functionality, and optimal performance under various loads.

DYN Fasteners manufactures torsion springs that can handle a wide range of torsional loads, from light-duty applications to heavy-duty industrial uses. We offer both standard and custom-designed torsion springs, tailored to meet specific needs. Whether it’s a small electronic device or a large industrial machine, our torsion springs provide unmatched reliability and strength.

Each torsion spring is engineered for exact specifications, using materials such as carbon steel, stainless steel, and alloy steel, ensuring high resilience against fatigue and corrosion. With DYN Fasteners, you can count on superior quality, precision, and excellent customer service.

- Torsion Springs Features: Durability, High-Performance, Custom Designs, High Load Capacity, Compact Design, Corrosion Resistance.

- Typical Applications: Automotive Industry, Consumer Electronics, Industrial Equipment, Aerospace, Furniture, Agriculture, Medical Equipment, Heavy Machinery, Doors & Locks.

- Finish Options: Zinc Plating, Chromate Conversion Coating, Black Oxide Coating, Powder Coating, Phosphating, A Stainless Steel, Custom Coatings.

Torsion Springs Size Guide and Specifications:

| Spring Type | Wire Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Free Length (mm) | Total Coils | Leg Length (mm) | Torque Capacity (Nm) | Solid Length (mm) |

| Light-Duty Torsion Springs | 0.5 – 2 | 5 – 30 | 3 – 25 | 10 – 50 | 3 – 5 | 5 – 20 | 0.1 – 1.0 | 4 – 15 |

| Medium-Duty Torsion Springs | 2 – 5 | 30 – 70 | 20 – 55 | 50 – 150 | 5 – 8 | 10 – 40 | 1.0 – 5.0 | 15 – 45 |

| Heavy-Duty Torsion Springs | 5 – 10 | 70 – 150 | 50 – 130 | 150 – 400 | 8 – 12 | 30 – 80 | 5.0 – 25.0 | 45 – 100 |

| Automotive Torsion Springs | 2 – 8 | 50 – 100 | 40 – 85 | 100 – 300 | 5 – 10 | 20 – 60 | 2.0 – 15.0 | 30 – 80 |

| Industrial Torsion Springs | 4 – 12 | 80 – 200 | 60 – 160 | 200 – 500 | 10 – 15 | 50 – 120 | 10.0 – 50.0 | 80 – 150 |

| Heavy Equipment Torsion Springs | 8 – 16 | 150 – 300 | 100 – 250 | 500 – 1000 | 15 – 20 | 70 – 150 | 20.0 – 100.0 | 150 – 250 |

| Custom Torsion Springs | 0.5 – 16 | 5 – 300 | 3 – 250 | Custom Sizes | Custom Coils | Custom Leg Length | Custom Torque Capacity | Custom Solid Length |

Custom sizes available on request, ensuring that we can meet your specific project requirements.

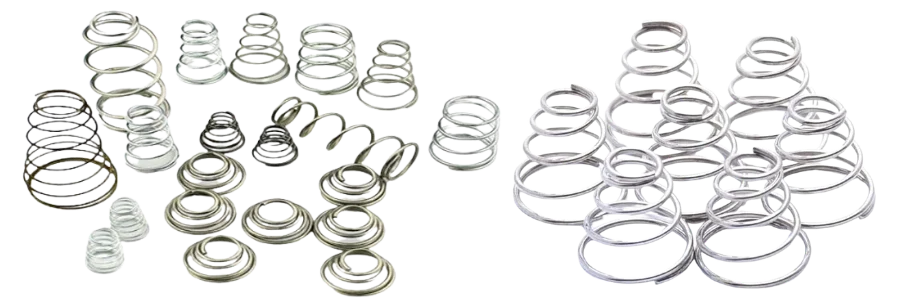

3. Precision Engineered Conical Springs for Optimal Performance

At DYN Fasteners, we specialize in manufacturing high-quality conical springs designed for versatility and durability. These springs, crafted from premium materials, are engineered to provide consistent load-bearing capabilities while maintaining superior resistance to wear and tear. Our conical springs are ideal for applications requiring precise control and compact spring designs, offering a reliable solution for a wide range of industries.

- Conical Springs Features: Durability, Precise Load Handling, Space-Saving Design, Versatile Performance, Customization, Corrosion Resistance.

- Typical Applications: Automotive Industry, Aerospace, Electronics, Industrial Machinery, Medical Equipment.

- Finish Options: Zinc Plating, Black Oxide, Phosphate Coating, Powder Coating, Chromate Conversion Coating, Polishing, Electroplating (Nickel, Chromium), Passivation (Stainless Steel).

| Size Range (Free Length) | Wire Diameter | Outer Diameter | Inner Diameter | Compressed Length | Solid Height |

| Small Conical Springs | 0.2 mm – 5 mm | 5 mm – 30 mm | 3 mm – 20 mm | 1 mm – 10 mm | 0.5 mm – 3 mm |

| Medium Conical Springs | 5 mm – 15 mm | 30 mm – 70 mm | 20 mm – 50 mm | 10 mm – 50 mm | 3 mm – 10 mm |

| Large Conical Springs | 15 mm – 40 mm | 70 mm – 150 mm | 50 mm – 120 mm | 50 mm – 200 mm | 10 mm – 30 mm |

4. BARREL SPRINGS

At DYN Fasteners, we are proud to offer barrel springs designed for optimal performance in a wide range of applications. Barrel springs, also known as Barrel Springs or “barrel-shaped” compression springs, are precision-engineered components that provide exceptional load-bearing capabilities. These springs are widely recognized for their ability to handle varying forces while maintaining compact design and durability.

Manufactured from high-quality materials such as carbon steel, stainless steel, and alloy steels, DYN Fasteners’ barrel springs are designed to deliver consistent and reliable performance. Whether you’re working with automotive parts, machinery, or specialized devices, our barrel springs provide the durability and efficiency you need to ensure smooth operation and longevity.

- Barrel Springs Features: Compact and Reliable, High Load Capacity, Durable and Resilient, Corrosion Resistance, Versatile Design, Customized Specifications.

- Typical Applications: Automotive Industry, Aerospace, Electronics, Industrial Machinery, Medical Equipment, Manufacturing

- Finish Options: Zinc Plating, Black Oxide, Phosphate Coating, Powder Coating, Chrome Plating, Electropolishing, Passivation.

| Wire Diameter Range (mm) | Small OD (mm) | Large OD (mm) | Free Length (mm) | Solid Length (mm) | Load Capacity (N) |

| 0.5 – 0.8 | 5 | 6 | 12 | 5 | 20 |

| 0.8 – 1.0 | 6 | 8 | 15 | 6 | 30 |

| 1.0 – 1.2 | 8 | 10 | 20 | 8 | 50 |

| 1.2 – 1.5 | 10 | 12 | 25 | 10 | 75 |

| 1.5 – 1.8 | 12 | 15 | 30 | 12 | 100 |

| 1.8 – 2.0 | 14 | 16 | 35 | 14 | 120 |

| 2.0 – 2.5 | 15 | 18 | 40 | 15 | 150 |

| 2.5 – 3.0 | 18 | 22 | 45 | 18 | 175 |

| 3.0 – 3.5 | 22 | 25 | 50 | 20 | 200 |

| 3.5 – 4.0 | 25 | 28 | 55 | 22 | 250 |

| 4.0 – 4.5 | 28 | 32 | 60 | 25 | 300 |

| 4.5 – 5.0 | 32 | 35 | 70 | 30 | 350 |

| 5.0 – 5.5 | 35 | 38 | 80 | 35 | 400 |

| 5.5 – 6.0 | 38 | 42 | 90 | 40 | 450 |

| 6.0 – 7.0 | 42 | 45 | 100 | 45 | 500 |

| 7.0 – 8.0 | 45 | 50 | 110 | 50 | 600 |

| 8.0 – 9.0 | 50 | 55 | 120 | 55 | 700 |

| 9.0 – 10.0 | 55 | 60 | 130 | 60 | 800 |

| 10.0 – 12.0 | 60 | 70 | 150 | 70 | 1000 |

| 12.0 – 15.0 | 70 | 80 | 180 | 80 | 1200 |

| 15.0 – 18.0 | 80 | 90 | 200 | 90 | 1500 |

5. Constant Force Springs

At DYN Fasteners, we specialize in manufacturing high-quality Constant Force Springs that offer consistent force across their entire range of motion. These springs are designed to deliver a constant load regardless of their deflection. Unlike traditional springs, the force produced by a constant force spring remains almost unchanged as it is extended, making it ideal for applications requiring uniform and reliable force.

DYN Fasteners ensures that each constant force spring is produced with precision, durability, and consistent performance. Our constant force springs are made from high-grade materials like stainless steel, carbon steel, and alloy steel, ensuring optimal tensile strength, fatigue resistance, and corrosion protection. These springs are wound tightly in a coil and can be extended in a controlled manner, making them suitable for a variety of mechanical devices.

We understand the importance of exact force specifications, which is why we work closely with customers to customize springs according to their specific requirements. Whether you need springs for delicate medical equipment, heavy-duty industrial machinery, or automotive applications, DYN Fasteners provides the perfect solution.

- Barrel Springs Features: Uniform Force Output, Compact Design, Customizable Length and Force, Fatigue Resistance, Corrosion-Resistant Options, Versatile Applications, Smooth and Controlled Extension, Energy Efficiency.

- Typical Applications: Automotive Industry, Aerospace, Electronics, Industrial Machinery, Medical Equipment, Manufacturing

- Finish Options: Zinc Plating, Black Oxide, Phosphate Coating, Powder Coating, Chrome Plating, Electropolishing, Passivation.

| Size Range (Free Length) | Wire Diameter | Outer Diameter (OD) | Inner Diameter (ID) | Thickness (T) | Radius of Curvature (R) | Maximum Load (N) | Compressed Length (mm) |

| Small Constant Force Springs | 0.10 mm – 1.00 mm | 5 mm – 20 mm | 3 mm – 15 mm | 0.10 mm – 0.30 mm | 2 mm – 5 mm | 1 N – 50 N | 5 mm – 50 mm |

| Medium Constant Force Springs | 1.00 mm – 3.00 mm | 20 mm – 50 mm | 10 mm – 40 mm | 0.30 mm – 0.80 mm | 5 mm – 12 mm | 50 N – 200 N | 50 mm – 150 mm |

| Large Constant Force Springs | 3.00 mm – 6.00 mm | 50 mm – 100 mm | 40 mm – 90 mm | 0.80 mm – 1.50 mm | 12 mm – 25 mm | 200 N – 500 N | 150 mm – 500 mm |

6. Variable Pitch Springs

DYN Fasteners offers high-quality Variable Pitch Springs designed for applications requiring a spring with a varying distance between coils. These springs are manufactured to meet precise specifications, providing a higher level of flexibility in design and performance.

Variable pitch springs are a type of compression spring where the spacing between the coils is not uniform, allowing for gradual changes in force over the length of the spring’s compression. This unique design enables Variable Pitch Springs to handle non-linear loads, providing both resistance and space efficiency for complex mechanisms.

At DYN Fasteners, we use advanced manufacturing techniques and high-grade materials to create Variable Pitch Springs that offer durability, high performance, and versatility. We cater to both standard and customized requirements, ensuring our springs meet specific load and dimensional needs for various industries.

- Variable Pitch Features: Non-linear Load Distribution, Customizable Design, Space Efficiency, High Performance, Durability and Strength, Smooth Operation.

- Typical Applications: Automotive Industry, Aerospace, Industrial Machinery, Electronics, Medical Devices, Consumer Goods, Energy Sector.

- Finish Options: Galvanized, Phosphate Coating, Powder Coating, Passivated, Electroplating, Natural Finish, Black Oxide Coating, Chrome Plating

| Size Range (Free Length) | Wire Diameter (mm) | Outer Diameter (mm) | Inner Diameter (mm) | Coil Diameter (mm) | Pitch Length (mm) | Compressed Length (mm) | Solid Height (mm) |

| Small Variable Pitch Springs | 0.2 – 5 | 5 – 30 | 3 – 20 | 2 – 10 | 2 – 15 | 1 – 10 | 0.5 – 3 |

| Medium Variable Pitch Springs | 5 – 15 | 30 – 70 | 20 – 50 | 10 – 50 | 5 – 30 | 10 – 50 | 3 – 10 |

| Large Variable Pitch Springs | 15 – 40 | 70 – 150 | 50– 120 | 20 – 80 | 10 – 50 | 50 – 200 | 10 – 30 |

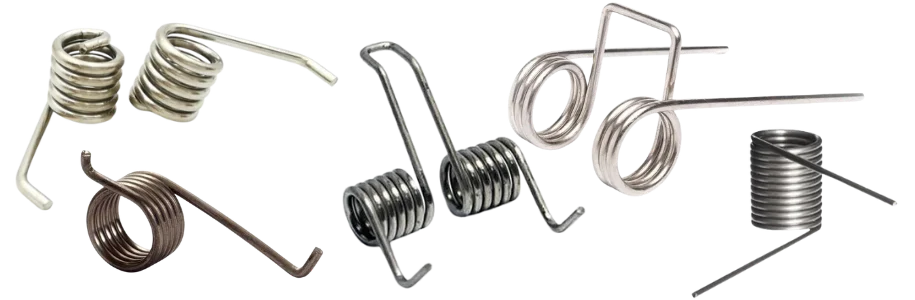

7. Helical Torsion Springs

DYN Fasteners is a leading exporter of Helical Torsion Springs, engineered to deliver exceptional performance and reliability in diverse applications. Designed with precision and crafted using high-grade materials, our Helical Torsion Springs are capable of storing and releasing angular energy efficiently. These springs provide resistance to rotational or twisting forces, making them ideal for a wide range of mechanical systems.

At DYN Fasteners, quality is our priority. Every Helical Torsion Spring is manufactured under strict quality control to meet international standards. Whether you need standard or custom-designed springs, we ensure that they meet the exact requirements of your application. With our advanced manufacturing techniques, we offer springs that excel in durability, flexibility, and consistent performance.

- Helical Torsion Springs Features: High Precision, Customizable Configurations, Durability, Compact Design, Material Versatility, Corrosion Resistance, Cost-Effective, Versatile Applications.

- Typical Applications: Automotive, Aerospace, Industrial Machinery, Agricultural Equipment, Construction, Consumer Goods, Medical Devices, Electronics.

- Finish Options: Zinc Plating, Nickel Plating, Black Oxide Coating, Electropolishing, Powder Coating, Phosphate Coating, Uncoated/Oil Finish.

| Wire Dia. (d) | Outer Dia. (OD) | Leg Length (L1/L2) | No. of Coils (N) | Torque (T) | Material |

| 0.5 mm | 5 mm | 20 mm/20 mm | 10 | 5 N·mm | Stainless Steel |

| 1.0 mm | 10 mm | 30 mm/30 mm | 15 | 25 N·mm | Carbon Steel |

| 2.0 mm | 20 mm | 50 mm/50 mm | 20 | 100 N·mm | Alloy Steel |

| 5.0 mm | 50 mm | 100 mm/100 mm | 25 | 500 N·mm | Spring Steel |

| 10.0 mm | 100 mm | 200 mm/200 mm | 30 | 1500 N·mm | Stainless Steel |

Coil Spring Materials Chemical Compositions & Mechanical Properties

- Standards:

ISO 10243, 2600

DIN 2095, 2096, 2097, 2093, 2708, 2098

ASTM A228, A229

BS 1726, 2895, 1726-2

SAE J800, J403

JIS B 2705, 2703, 2704

EN 10270-1, 13906, 10270-3

IS 4454 (Part 1) - Certifications: CE Certification, RoHS Compliant, REACH Compliance.