NUTS

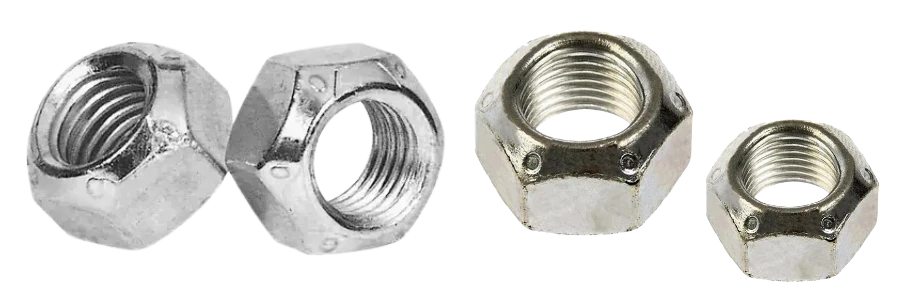

1. Hex Nuts – Essential Fasteners for Reliable Connections

Features of Regular Hex Nuts: Hexagonal Shape, Precision Internal Threading, High Load Capacity, Corrosion Resistance, Versatility.

Typical Applications: Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Automotive and Aerospace, Securing engine parts, chassis components, and assemblies in vehicles and aircraft, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications.

Finish Options: Zinc-Plated Hex Nut, Hot-Dip Galvanized Hex Nut, Black Oxide Hex Nut, Passivated Finish Hex Nut.

- Features of Regular Hex Nuts: Hexagonal Shape, Precision Internal Threading, High Load Capacity, Corrosion Resistance, Versatility.

- Typical Applications: Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Automotive and Aerospace, Securing engine parts, chassis components, and assemblies in vehicles and aircraft, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications.

- Finish Options: Zinc-Plated Hex Nut, Hot-Dip Galvanized Hex Nut, Black Oxide Hex Nut, Passivated Finish Hex Nut.

Standard Sizes and Dimensions:

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 5 | 2.5 | DIN 934 |

| M8 | 1.25 | 13 | 6.5 | 5 | DIN 934 |

| M10 | 1.5 | 17 | 8 | 10 | DIN 934 |

| M12 | 1.75 | 19 | 10 | 15 | DIN 934 |

| M16 | 2 | 24 | 12 | 28 | DIN 934 |

Custom sizes and specifications are available upon request.

2. Nylon Insert Lock Nuts – Reliable Fasteners for Secure Connections

Nylon insert lock nuts, often referred to as nylon lock nuts or simply lock nuts, are essential fasteners designed to prevent loosening due to vibration and dynamic loads. Their unique design features a nylon insert that grips the threads of the bolt, ensuring a secure connection in various applications. These nuts are widely used across multiple industries, including automotive, construction, and machinery, where reliability and safety are paramount.

At DYN Fasteners, we offer high-quality nylon insert lock nuts made from premium materials, available in a range of sizes and grades to meet your specific needs.

- Features of Nylon Insert Lock Nuts: Vibration Resistance, Easy Installation, Durability, Lightweight, Versatile Applications.

- Typical Applications: Automotive and Aerospace, Fastening engine parts, chassis components, and critical systems in vehicles and aircraft, Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications.

- Finish Options: Zinc-Plated Nylon Insert Lock Nuts, Hot-Dip Galvanized Nylon Insert Lock Nuts, Black Oxide Nylon Insert Lock Nuts, Passivated Finish Nylon Insert Lock Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 5 | 2.5 | DIN 985 |

| M8 | 1.25 | 13 | 6.5 | 5 | DIN 985 |

| M10 | 1.5 | 17 | 8 | 10 | DIN 985 |

| M12 | 1.75 | 19 | 10 | 15 | DIN 985 |

| M16 | 2 | 24 | 12 | 28 | DIN 985 |

3. Serrated Flange Lock Nuts – Enhanced Grip for Secure Fastening

Serrated flange lock nuts are specialized fasteners designed to provide superior grip and prevent loosening due to vibration and dynamic loads. Their unique serrated flange creates a locking mechanism that enhances the nut’s resistance to loosening, making them ideal for applications where safety and reliability are paramount. These nuts are widely used in various industries, including automotive, construction, and manufacturing, where secure connections are critical.

At DYN Fasteners, we offer high-quality serrated flange lock nuts made from premium materials, available in various sizes and grades to meet your specific needs.

- Features of Serrated Flange Lock Nuts: Serrated Design, Integrated Flange, Easy Installation, Durability, Versatile Applications,

- Typical Applications: Automotive and Aerospace, Fastening engine parts, chassis components, and critical systems in vehicles and aircraft, Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications,

- Finish Options: Zinc-Plated Serrated Flange Lock Nuts, Hot-Dip Galvanized Serrated Flange Lock Nuts, Black Oxide Serrated Flange Lock Nuts, Passivated Finish Serrated Flange Lock Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 6.5 | 3 | DIN 6923 |

| M8 | 1.25 | 13 | 7.5 | 6 | DIN 6923 |

| M10 | 1.5 | 17 | 8.5 | 12 | DIN 6923 |

| M12 | 1.75 | 19 | 9.5 | 18 | DIN 6923 |

| M16 | 2 | 24 | 11.5 | 30 | DIN 6923 |

4. Prevailing Torque Lock Nuts – Reliable Locking Solutions for Secure Assemblies

Prevailing torque lock nuts are innovative fasteners designed to resist loosening due to vibrations and dynamic loads. Utilizing a unique thread design that creates friction during installation, these nuts provide exceptional locking capabilities without the need for additional locking devices. Prevailing torque lock nuts are widely used in various applications across multiple industries, ensuring that assemblies remain secure even in the most demanding environments.

At DYN Fasteners, we offer premium quality prevailing torque lock nuts, available in a variety of materials and sizes to cater to your specific needs.

- Features of Prevailing Torque Lock Nuts: High Resistance to Vibration, No Additional Locking Device Needed, Ease of Installation, Durability, Versatile Applications.

- Typical Applications: Automotive and Aerospace, Fastening engine parts, chassis components, critical systems in vehicles and aircraft, Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Manufacturing and Machinery, Fastening machine components, conveyors, industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications,

- Finish Options: Zinc-Plated Prevailing Torque Lock Nuts, Hot-Dip Galvanized Prevailing Torque Lock Nuts, Black Oxide Prevailing Torque Lock Nuts, Passivated Finish Prevailing Torque Lock Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 6.5 | 3 | DIN 985 |

| M8 | 1.25 | 13 | 7.5 | 6 | DIN 985 |

| M10 | 1.5 | 17 | 8.5 | 12 | DIN 985 |

| M12 | 1.75 | 19 | 9.5 | 18 | DIN 985 |

| M16 | 2 | 24 | 11.5 | 30 | DIN 985 |

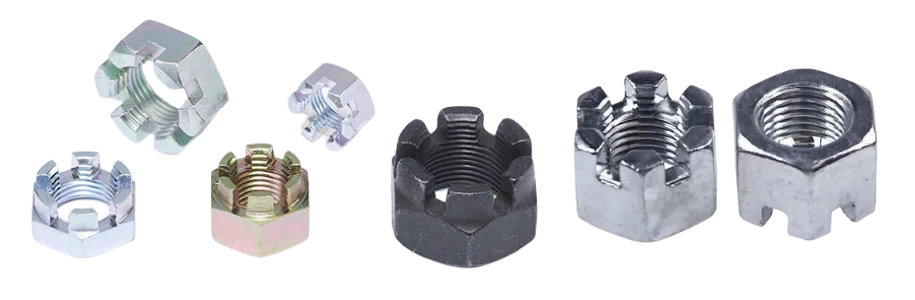

5. Castle Nuts – Reliable Locking Solutions for Secure Fastening

Castle nuts, also known as slotted nuts, are specialized fasteners featuring a unique design that includes slots or notches around the circumference. These nuts are typically used in conjunction with a cotter pin or a safety wire to secure them in place, preventing loosening due to vibration or dynamic loads. Castle nuts are widely used in various applications across multiple industries, especially where safety and reliability are critical.

At DYN Fasteners, we offer high-quality castle nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of Castle Nuts: Unique Design, High Resistance to Vibration, Ease of Installation, Durability, Versatile Applications.

- Typical Applications: Automotive and Aerospace, Fastening wheel assemblies, suspension components, and critical systems in vehicles and aircraft, Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household applications.

- Finish Options: Zinc-Plated Castle Nuts , Hot-Dip Galvanized Castle Nuts, Black Oxide Castle Nuts, Passivated Finish Castle Nuts.

Standard Sizes and Dimensions:

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 7 | 3 | DIN 935 |

| M8 | 1.25 | 13 | 9 | 5 | DIN 935 |

| M10 | 1.5 | 17 | 11 | 10 | DIN 935 |

| M12 | 1.75 | 19 | 12 | 15 | DIN 935 |

| M16 | 2 | 24 | 15 | 25 | DIN 935 |

Custom sizes and specifications are available upon request.

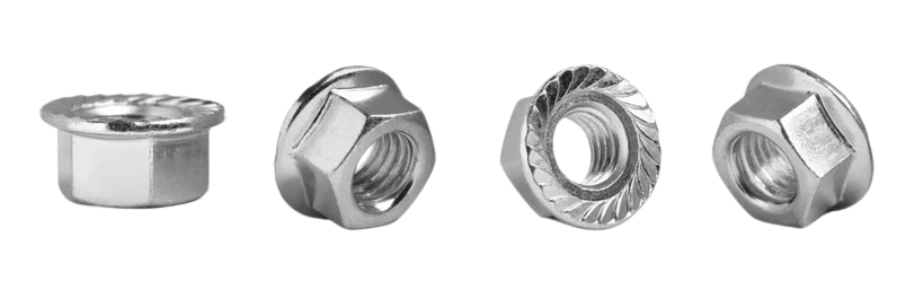

6. Flange Nuts – Enhanced Stability and Load Distribution

Flange nuts, also known as flange lock nuts or flange hex nuts, are specialized fasteners designed with an integrated flange at the base. This flange increases the nut’s surface area, allowing for better load distribution and enhanced stability when fastening components. Flange nuts are ideal for applications where a secure, stable connection is crucial, especially in environments subject to vibration and movement.

At DYN Fasteners, we provide high-quality flange nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of Flange Nuts: Integrated Flange Design, Self-Locking Properties, Ease of Installation, Durability, Versatile Applications.

- Typical Applications: Automotive and Aerospace, Fastening engine parts, chassis components, and critical systems in vehicles and aircraft, Construction and Infrastructure, Fastening steel structures, supporting frameworks, and anchoring heavy equipment, Manufacturing and Machinery, Fastening machine components, conveyors, and industrial equipment, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and assembling electrical equipment, DIY and Furniture Assembly, Assembling furniture, attaching shelving, and general household application.

- Finish Options: Zinc-Plated Flange Nuts, Hot-Dip Galvanized Flange Nuts, Black Oxide Flange Nuts, Passivated Finish Flange Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Flange Diameter (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 6.5 | 12 | 4 | DIN 6923 |

| M8 | 1.25 | 13 | 7.5 | 16 | 8 | DIN 6923 |

| M10 | 1.5 | 17 | 9.5 | 20 | 12 | DIN 6923 |

| M12 | 1.75 | 19 | 11.5 | 24 | 20 | DIN 6923 |

| M16 | 2 | 24 | 15 | 30 | 30 | DIN 6923 |

7. Wing Nuts – Convenient and Easy-to-Use Fasteners

Wing nuts are a type of fastener characterized by two large “wings” that extend from the sides of the nut, allowing for easy manual tightening and loosening without the need for tools. This design makes wing nuts particularly useful in applications where frequent adjustments or removals are required. They are commonly used in various industries, including woodworking, automotive, and equipment assembly.

At DYN Fasteners, we offer high-quality wing nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of Wing Nuts: Easy Manual Operation, Versatile Applications, Quick Assembly and Disassembly, Durability, Lightweight Design.

- Typical Applications: Woodworking and Furniture, Fastening table legs, securing shelves, and assembling cabinets, Automotive and Equipment Assembly, Fastening engine covers, securing battery terminals, and attaching equipment, Manufacturing and Machinery, Securing machine parts, attaching guards, and facilitating equipment maintenance, DIY Projects, Assembling furniture, attaching shelving, and general household applications,

- Finish Options: Zinc-Plated Wing Nuts, Hot-Dip Galvanized Wing Nuts, Nickel Plated Wing Nuts.

Standard Sizes and Dimensions:

| Nut Size (mm) | Thread Pitch (mm) | Width Across Wings (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 12 | 10.5 | 5 | DIN 316 |

| M8 | 1.25 | 16 | 12 | 8 | DIN 316 |

| M10 | 1.5 | 20 | 14 | 12 | DIN 316 |

| M12 | 1.75 | 24 | 16 | 18 | DIN 316 |

| M16 | 2 | 30 | 18 | 28 | DIN 316 |

Custom sizes and specifications are available upon request.

8. Cap Nuts – Secure and Protective Fasteners

Cap nuts, also known as acorn nuts or dome nuts, are specialized fasteners designed with a domed shape that covers the end of a bolt or screw. This design not only provides a finished appearance but also protects the threads of the bolt from dirt, debris, and potential damage. Cap nuts are widely used in various applications where a neat and secure finish is required.

At DYN Fasteners, we offer high-quality cap nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of Cap Nuts: Domed Design, Thread Protection, Easy Installation, Durability, Versatile Applications.

- Typical Applications: Automotive and Machinery, Fastening engine components, securing brackets, and covering exposed bolts, Construction and Infrastructure, Fastening steel structures, securing railings, and covering exposed bolts in building projects, Furniture and Home Décor, Assembling tables, securing chairs, and finishing off shelving units, Electrical and Electronics, Fastening electrical panels, securing circuit boards, and covering exposed screws.

- Finish Options: Zinc-Plated Cap Nuts, Hot-Dip Galvanized Cap Nuts, Polished Finish Cap Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 10 | 8 | 4 | DIN 1587 |

| M8 | 1.25 | 13 | 10 | 6 | DIN 1587 |

| M10 | 1.5 | 17 | 12 | 10 | DIN 1587 |

| M12 | 1.75 | 19 | 14 | 14 | DIN 1587 |

| M16 | 2 | 24 | 18 | 20 | DIN 1587 |

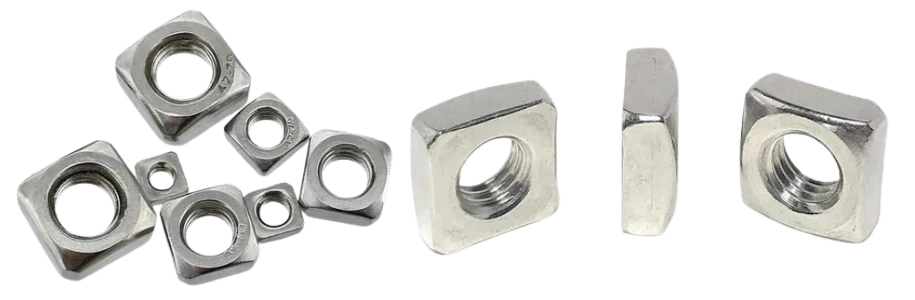

9. Square Nuts – Versatile and Reliable Fasteners

Square nuts are a type of fastener characterized by their square shape, which allows for easy alignment and stability during assembly. They are designed to be used with bolts and screws to provide a secure connection in various applications. Square nuts are particularly useful in situations where greater surface area and resistance to loosening are required.

At DYN Fasteners, we offer high-quality square nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of Square Nuts: Stable Shape, Versatile Applications, Ease of Use, Durability, Variety of Sizes.

- Typical Applications: Construction and Infrastructure, Fastening steel structures, securing frameworks, and assembling scaffolding, Manufacturing and Machinery, Securing machine parts, attaching components, and facilitating equipment maintenance, Furniture Assembly, Assembling tables, chairs, and cabinets, Electrical and Electronics, Fastening electrical enclosures, securing circuit boards, and covering exposed screws.

- Finish Options: Zinc-Plated Square Nuts, Hot-Dip Galvanized Square Nuts, Nickel Plated Square Nuts.

Standard Sizes and Dimensions:

| Nut Size (mm) | Thread Pitch (mm) | Width Across Flats (mm) | Height (mm) | Weight (g) | Standard |

| M4 | 0.7 | 7 | 4 | 1 | DIN 557 |

| M5 | 0.8 | 8 | 5 | 2 | DIN 557 |

| M6 | 1 | 10 | 6 | 3 | DIN 557 |

| M8 | 1.25 | 12 | 8 | 5 | DIN 557 |

| M10 | 1.5 | 14 | 9 | 8 | DIN 557 |

Custom sizes and specifications are available upon request.

10. T-Nuts – Reliable Fasteners for Wood and Metal Applications

T-nuts, also known as tee nuts, are a type of fastener designed to provide a secure connection in wood and metal applications. Characterized by their unique shape, T-nuts feature a cylindrical body with prongs that embed into the material, creating a strong anchor point for bolts and screws. They are widely used in furniture assembly, woodworking, and machinery, offering versatility and ease of installation.

At DYN Fasteners, we offer high-quality T-nuts made from premium materials, available in various sizes and specifications to meet your specific needs.

- Features of T-Nuts: Strong Grip, Ease of Installation, Versatile Applications, Durability, Smooth Finish.

- Typical Applications: Furniture Assembly, Attaching legs to tables, securing backs to chairs, and assembling cabinetry, Woodworking, Connecting panels, securing frames, and fastening hardware, Metal Fabrication, Assembling machinery, securing equipment, and connecting structural components, DIY and Home Improvement, Fastening shelving units, assembling workbenches, and securing fittings.

- Finish Options: Zinc-Plated T-Nuts, Hot-Dip Galvanized T-Nuts, Nickel Plated T-Nuts.

| Nut Size (mm) | Thread Pitch (mm) | Outer Diameter (mm) | Height (mm) | Weight (g) | Standard |

| M6 | 1 | 12 | 10 | 3 | DIN 1587 |

| M8 | 1.25 | 14 | 12 | 5 | DIN 1587 |

| M10 | 1.5 | 16 | 14 | 8 | DIN 1587 |

| M12 | 1.75 | 18 | 16 | 10 | DIN 1587 |

| M16 | 2 | 22 | 20 | 15 | DIN 1587 |

Nuts Materials / Grades

Materials | Grades |

Stainless Steel | ASTM / ASME SA 312 GR. TP 304, 304L, 304H, 309S ,309H, 310S, 310H, 316, 316TI, 316H, 316 LN, 317, 317L, 321, 321H, 347, 347 H, 904L. |

High Tensile | 8.8, 10.9, 12.9, 14.9 |

Duplex Steel | UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

Carbon Steel | ASTM / ASME A 335 GRP 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91 |

Alloys Steel | ASTM / ASME A/SA 193 / 194 – B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

- Standards:

ASTM A194.

ISO 4032,7040,4161,4033.

DIN 934,985,6923,935,316,1587,557.

SAE J995. - Certifications: CE Certification, RoHS Compliant, REACH Compliance.

Nuts Materials / Grades

| Materials | Grades |

| Stainless Steel | ASTM / ASME SA 312 GR. TP 304, 304L, 304H, 309S ,309H, 310S, 310H, 316, 316TI, 316H, 316 LN, 317, 317L, 321, 321H, 347, 347 H, 904L. |

| High Tensile | 8.8, 10.9, 12.9, 14.9 |

| Duplex Steel | UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

| Carbon Steel | ASTM / ASME A 335 GRP 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91 |

| Alloys Steel | ASTM / ASME A/SA 193 / 194 – B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750, Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

- Standards:

ASTM A194.

ISO 4032,7040,4161,4033.

DIN 934,985,6923,935,316,1587,557.

SAE J995. - Certifications: CE Certification, RoHS Compliant, REACH Compliance.