SCREWS

1. Machine Screws – Essential Fasteners for Precision Applications

- Features of Machine Screws: Versatile Applications, Consistent Threading, Easy Installation, Durable Construction, Customizable Options.

- Typical Applications: Electronics, securing components in electronic devices, circuit boards and enclosures, Automotive Industry, Engine parts, interior components and electrical systems, Construction, Structural connections in metal frameworks, HVAC systems and equipment installation, Furniture Manufacturing, Assembly of modular furniture and securing hardware components, Aerospace & Defense, Used in precision applications requiring high strength and lightweight solutions, Marine Industry, Ideal for corrosion-resistant applications in ships and offshore equipment.

- Finish Options: Zinc-Plated Machine Screws, Black Oxide Machine Screws, Nickel Plated Machine Screws, Polished Stainless Steel Machine Screws.

- Thread Types: coarse threads, fine threads

| Screw Size | Length (mm) | Diameter (mm) | Thread Pitch (mm) | Head Type |

| M3 | 6 – 50 | 3 | 0.5 | Pan, Flat, Hex |

| M4 | 8 -60 | 4 | 0.7 | Pan, Flat, Hex |

| M5 | 10 – 70 | 5 | 0.8 | Pan, Flat, Hex |

| M6 | 12 – 80 | 6 | 1 | Pan, Flat, Hex |

| M8 | 16 – 100 | 8 | 1.25 | Pan, Flat, Hex |

| M10 | 20 – 120 | 10 | 1.5 | Pan, Flat, Hex |

2. Reliable Threads for Stronger Connections – Perfect for Woodwork

Wood screws are essential fasteners used in woodworking projects to securely join wooden components. These screws feature sharp, tapered threads that bite into wood fibers for a strong and durable hold. Available in various head types, lengths, and thread styles, wood screws are designed to prevent splitting and ensure stability in diverse applications.

At DYN Fasteners, our wood screws are manufactured with precision, offering superior corrosion resistance, high strength, and a variety of finishes. Our screws ensure lasting performance, even in demanding environments, making them the ideal choice for professionals and DIY enthusiasts alike.

- Features of Machine Screws: Sharp Threads, Variety of Head Types, Corrosion Resistant, Self-Tapping Design, Strong Holding Power, Customizable Sizes.

- Typical Applications: Furniture Manufacturing, Assembly of wooden furniture, cabinets, and modular units, Construction, Structural framing, decking, and roofing applications, Carpentry, Fixing trims, moldings, and wooden fixtures, DIY Projects, Ideal for hobbyists and small-scale woodworking projects, Outdoor Applications, Fencing, wooden play structures, and garden furniture (stainless or coated screws), Marine Industry, Woodwork in boats and docks using corrosion-resistant materials.

- Finish Options: Zinc-Coated Machine Screws, Galvanized Machine Screws, Black Oxide Machine Screws, Brass-Plated Machine Screws, Polished Stainless Steel Machine Screws.

- Thread Types: Coarse Thread, Fine Thread.

Imperial Sizes (Diameter × Length)

| Diameter (mm) | Common Lengths (mm) | Applications |

| 3 mm | 10, 15, 20, 25, 30, 40 mm | For lightweight wood panels, small trims, and craft projects. |

| 4 mm | 15, 20, 25, 30, 40, 50 mm | Securing medium-weight materials like plywood and MDF sheets. |

| 5 mm | 20, 25, 30, 40, 50, 60 mm | Used in furniture assembly, cabinetry, and DIY woodworking. |

| 6 mm | 25, 30, 40, 50, 60, 80 mm | General construction tasks, including securing wooden beams and frames. |

| 8 mm | 40, 50, 60, 80, 100 mm | Heavy-duty wood connections, outdoor projects, and decking. |

| 10 mm | 80, 100, 120, 150, 200 mm | For structural woodwork, securing large beams, and heavy construction applications. |

| Diameter (Inches) | Common Lengths (Inches) | Applications |

| 1/8″ | 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″ | For lightweight materials like trim, small wood joints, and general DIY tasks. |

| 3/16″ | 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″ | Securing plywood, particleboard, and medium-sized wooden parts. |

| 1/4″ | 1 1/2″, 2″, 2 1/2″, 3″, 4″ | Suitable for larger furniture assembly, wooden frameworks, and cabinetry. |

| 5/16″ | 2 1/2″, 3″, 4″, 5″, 6″ | Heavy-duty wood connections, outdoor wood structures, and fencing. |

| 3/8″ | 4″, 5″, 6″, 7″, 8″ | Structural woodwork, decking, and securing large beams in heavy construction tasks. |

3. Self-Tapping Screws – Precision Fastening Made Easy – Build Stronger with DYN Fasteners

- Features of Self-Tapping Screws: Self-Drilling Capability, Versatile Applications, Secure Grip, Variety of Head Types, Corrosion Resistant, Durable Construction, Customizable Options.

- Typical Applications: Construction, Roofing, siding, framing applications, Automotive, Assembly of body panels, interiors, and component, Electrical, Fixing electrical enclosures, junction boxes, and equipment, Furniture, Assembling cabinets, desks, and modular units, Marine, Corrosion-resistant applications for docks, boats, and coastal structures, HVAC Systems, Fastening ducts, vents, and metal sheets.

- Finish Options: Zinc-Coated Self-Tapping Screws, Galvanized Self-Tapping Screws, Black Oxide Self-Tapping Screws, Polished Stainless Steel Self-Tapping Screws, Phosphate Coating Self-Tapping Screws.

| Size | Length Range (mm) | Diameter (mm) | Thread Pitch (mm) | Head Type |

| #4 | 10 – 50 | 3.5 | 0.8 | Pan, Flat, Hex |

| #6 | 12 – 70 | 4.2 | 1 | Pan, Flat, Hex |

| #8 | 16 – 80 | 4.8 | 1.2 | Pan, Flat, Hex |

| #10 | 20 – 100 | 5.5 | 1.5 | Pan, Flat, Hex |

| #12 | 25 – 120 | 6.5 | 1.75 | Pan, Flat, Hex |

| M3 | 8 – 50 | 3 | 0.5 | Pan, Flat, Hex |

| M4 | 10 – 60 | 4 | 0.7 | Pan, Flat, Hex |

4. Precision Drilling and Lasting Grip with DYN Self-Drilling Screws

Self-drilling screws are advanced fasteners that combine the functionality of a drill bit and a screw in one. Designed for effortless drilling into various materials, these screws eliminate the need for pre-drilling, significantly reducing installation time and improving efficiency.

Our self-drilling screws are precision-engineered for durability, corrosion resistance, and superior holding power. With consistent performance and high-quality materials, DYN Fasteners ensures your projects are built to last.

- Features of Self-Drilling Screws: Built-in drill point for seamless penetration, Eliminates the need for pre-drilling, High corrosion resistance with various finish options, Designed for quick and reliable fastening, Available in multiple sizes and materials to suit diverse applications.

- Typical Applications: Construction, Roofing, cladding, and steel framing, Automotive, Vehicle assembly and repair, Electrical, Fastening components in panels and enclosures, HVAC, Ductwork and equipment installations, Furniture, Durable assembly for metal and wooden furniture.

- Finish Options: Zinc Plating, Black Oxide, Nickel Plating, Galvanized, Phosphate Coatin.

| Size | Length Range (mm) | Diameter (mm) | Thread Pitch (mm) | Head Type |

| #8 | 16 – 100 | 4.2 | 1 | Pan, Flat, Hex |

| #10 | 20 – 120 | 4.8 | 1.5 | Pan, Flat, Hex |

| #12 | 25 – 150 | 6.5 | 1.75 | Pan, Flat, Hex |

| M4 | 10 – 60 | 4 | 0.7 | Pan, Flat, Hex |

| M5 | 12 – 70 | 5 | 0.8 | Pan, Flat, Hex |

| M6 | 16 – 80 | 6 | 1 | Pan, Flat, Hex |

5. DYN Drywall Screws – Precision, Strength, and Seamless Fastening

Drywall screws are specialized fasteners designed for securing drywall sheets to wood or metal studs. These screws feature sharp points, coarse or fine threads, and countersunk heads to ensure flush installation.

DYN Fasteners offers high-performance drywall screws that deliver optimal strength, superior corrosion resistance, and effortless application, making them a trusted choice for professionals and DIY enthusiasts alike.

- Features of Drywall Screws: Sharp Points, Thread Design, Corrosion Resistance, Countersunk Heads, High Strength.

- Typical Applications: Construction: Fastening drywall panels to wooden or metal frames, Interior Design, Installation of gypsum boards for ceilings and walls, DIY Projects, Home renovations and custom interior installations, Commercial Spaces, Partitions and drywall for offices and retail spaces.

- Finish Options: Black Phosphate Coating Drywall Screws, Zinc Plating Drywall Screws, Stainless Steel Drywall Screws.

| Size | Length Range (mm) | Diameter (mm) | Thread Type | Head Type |

| #6 | 25 – 100 | 3.5 | Coarse | Bugle |

| #8 | 25 – 150 | 4.2 | Coarse | Bugle |

| #10 | 30 – 200 | 4.8 | Coarse | Bugle |

| M3.5 | 20 – 80 | 3.5 | Coarse | Bugle |

| M4 | 25 – 100 | 4 | Coarse | Bugle |

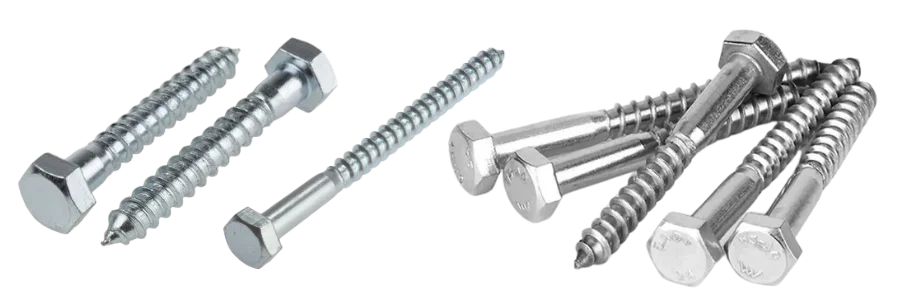

6. DYN Coach Screws – Built to Anchor and Endure

Coach screws, also known as lag screws, are heavy-duty fasteners designed for securing materials such as wood, metal, or concrete. These screws feature a hexagonal head and coarse threading, providing excellent holding power in high-load applications.

DYN Fasteners offers premium-quality coach screws manufactured from durable materials, ensuring superior performance in demanding environments. Whether for construction, woodworking, or heavy engineering, our coach screws provide reliable anchoring solutions.

- Features of Coach or Lag Screws: Hexagonal Head, Coarse Threads, Easy Installation, High Load Capacity, Customizable Dimensions, Versatile Usage.

- Typical Applications: Construction, Timber framing, roofing, and flooring, Securing beams, posts, and other structural components, Furniture Manufacturing, Heavy-duty wooden furniture assembly, Electrical Installations, Mounting equipment and securing panels, Industrial Applications, Machinery installations and repairs, Fencing & Landscaping, Fixing fence posts, garden structures, and decking.

- Finish Options: Zinc-Plated Coach or Lag Screws, Hot-Dip Galvanized Coach or Lag Screws, Black Oxide Coach or Lag Screws, Polished Stainless Steel Coach or Lag Screws.

| Size | Length Range (mm) | Diameter (mm) | Thread Pitch (mm) | Head Type |

| 1/4″ | 25 – 150 | 6.4 | 1.5 | Hex |

| 5/16″ | 30 – 200 | 7.9 | 1.6 | Hex |

| 3/8″ | 40 – 250 | 9.5 | 1.7 | Hex |

| 1/2″ | 50 – 300 | 12.7 | 1.9 | Hex |

SCREW Materials / Grades

Carbon Steel Grades

| Grade | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

| SAE 1010 | 0.08-0.13% | 0.30-0.60% | ≤ 0.04% | ≤ 0.05% | ≤ 0.10% |

| SAE 1020 | 0.18-0.23% | 0.30-0.60% | ≤ 0.04% | ≤ 0.05% | ≤ 0.10% |

Stainless Steel Grades

| Grade | Carbon (C) | Chromium (Cr) | Nickel (Ni) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Molybdenum (Mo) |

| AISI 304 | ≤ 0.08% | 18-20% | 8-10.5% | 2.00% | ≤ 0.045% | ≤ 0.03% | 1.00% | – |

| AISI 316 | ≤ 0.08% | 16-18% | 10-14% | 2.00% | ≤ 0.045% | ≤ 0.03% | 1.00% | 2-3% |

Brass Grades

| Grade | Copper (Cu) | Zinc (Zn) | Lead (Pb) | Iron (Fe) | Other Elements |

| CZ121 | 57-59% | Balance | 2.5-3.5% | ≤ 0.30% | ≤ 0.10% |

| CZ122 | 60-63% | Balance | ≤ 0.20% | ≤ 0.30% | ≤ 0.10% |

Alloy Steel Grades

| Grade | Carbon (C) | Chromium (Cr) | Nickel (Ni) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Molybdenum (Mo) |

| AISI 4140 | 0.38-0.43% | 0.80-1.10% | – | 0.75-1.00% | ≤ 0.035% | ≤ 0.040% | 0.15-0.30% | 0.15-0.25% |

| AISI 8620 | 0.18-0.23% | 0.40-0.60% | 0.40-0.70% | 0.70-0.90% | ≤ 0.025% | ≤ 0.035% | 0.15-0.35% | 0.15-0.25% |

SCREW Mechanical Properties

Carbon Steel Grades

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| SAE 1010 | 340-470 | 200-280 | 25-35 | 111-135 |

| SAE 1020 | 410-550 | 240-370 | 23-35 | 121-143 |

Stainless Steel Grades

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| AISI 304 | 505-745 | 215-290 | 40-50 | 170-210 |

| AISI 316 | 515-750 | 205-290 | 35-50 | 170-200 |

Brass Grades

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| CZ121 | 360-500 | 150-200 | 15-30 | 100-150 |

| CZ122 | 350-460 | 120-180 | 25-35 | 90-140 |

Alloy Steel Grades

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| AISI 4140 | 655-1020 | 415-850 | 20-35 | 197-269 |

| AISI 8620 | 620-865 | 345-585 | 20-30 | 149-223 |

SCREW Mechanical Properties

- Standards:

ASTM A193,1667, C1513, C1002. B18.2.1.

ISO 3506,7045, 7046, 1478,15481,4759-1.

DIN 7985, 97, 912, 7504, 18182,571.

IS 6736.

BS 1210, EN ISO 3506, 4174.

ANSI B18.6.1, B18.6.4.

JIS B 1122.